Rail Services Engineered for Performance

Field-tested Innovation

Evorail delivers precision engineering and field-tested innovation across every layer of locomotive operations. From full rebuilds to intelligent control upgrades, our services are designed to extend asset life, reduce downtime, and meet the evolving demands of modern rail networks.

Locomotive Rebuild and Upgrade

Locomotive Rebuild and Upgrade

- Extended asset life and lower capital cost through delaying costly fleet replacement and lowering total lifecycle expenditure.

- Improved reliability and availability; Overhauled components and modernized systems reduce breakdowns, increase mean time between failures, and boost fleet uptime for predictable operations.

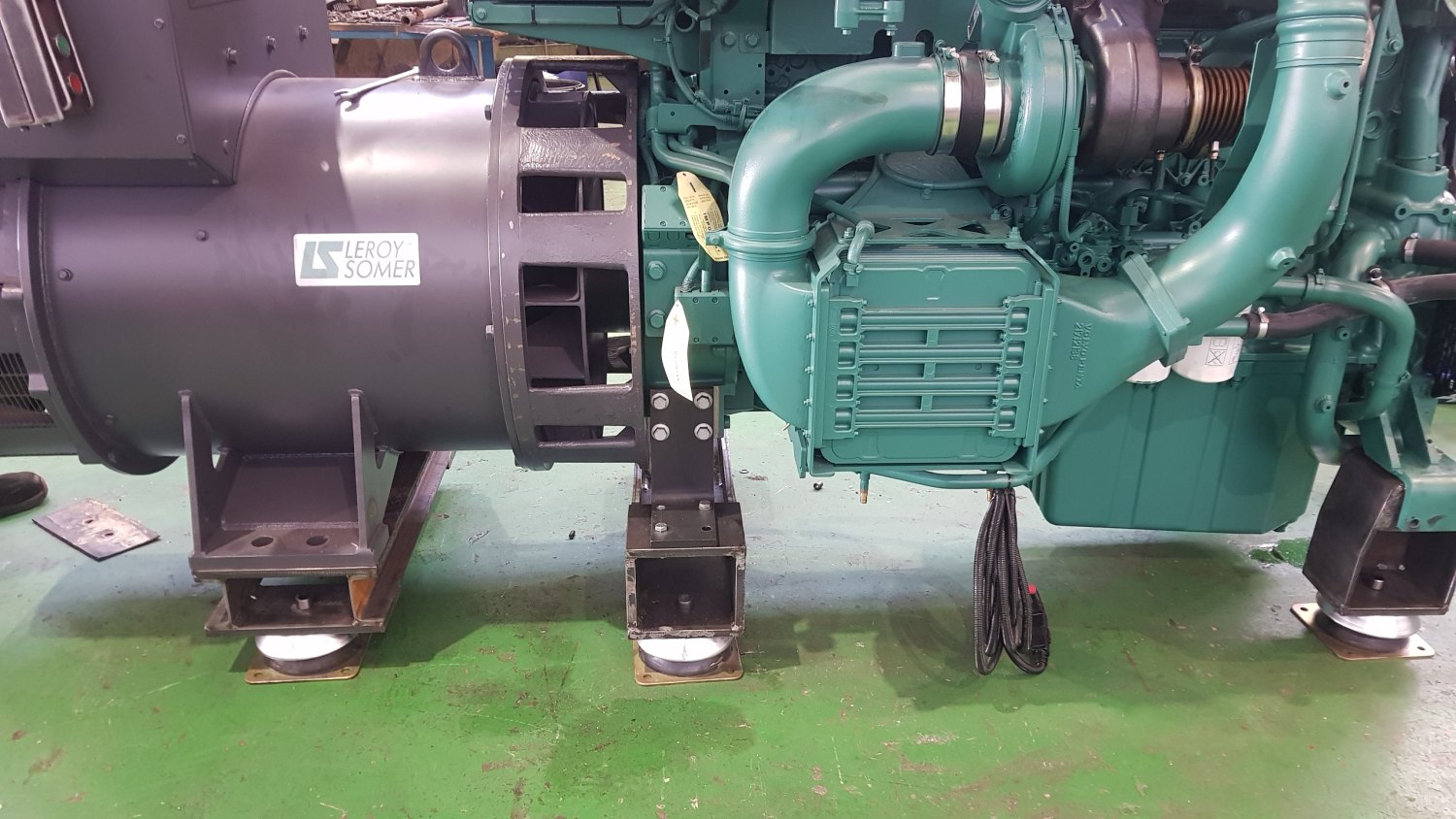

- Engine upgrades, fuel-system tuning, and control-system improvements reduce fuel consumption and cut daily operating expenses.

- Powertrain, traction control, braking, and electronic systems can be upgraded to improve tractive effort, acceleration, top speed, and train-handling performance.

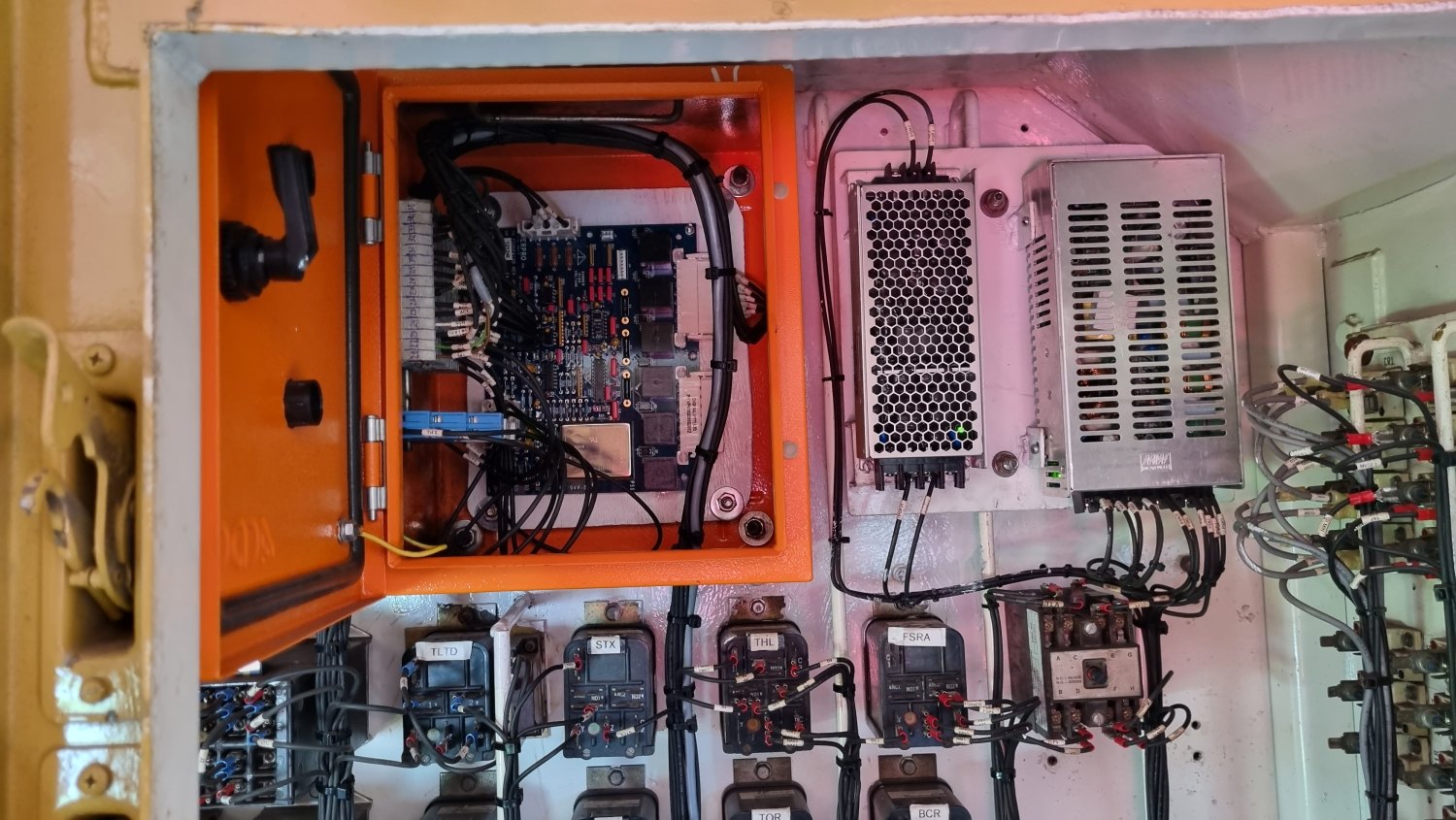

- Modernized braking, diagnostics, visibility, collision-avoidance systems, and cab ergonomics enhance safety, reduce human error, and improve working conditions.

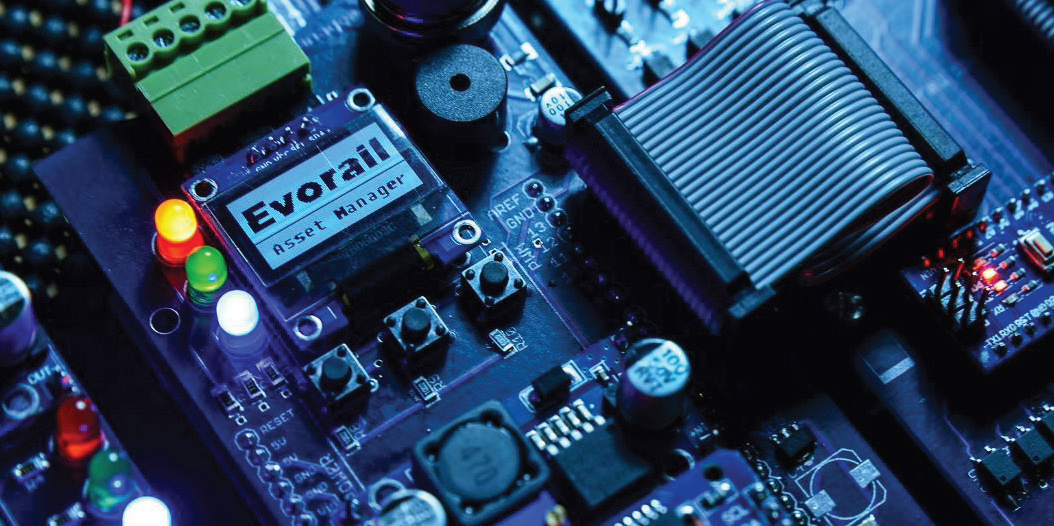

- Adding modern monitoring, telematics, and predictive-maintenance systems enables condition-based maintenance, reduces downtime, and optimizes spare-parts inventories.

- Upgrading known platforms preserves operational familiarity, simplifies crew training, and reduces integration risks compared with adopting entirely new models.

- For a tailored assessment—cost estimates, expected fuel and emissions savings, and optimal upgrade scope for your fleet—contact us to arrange a technical audit.

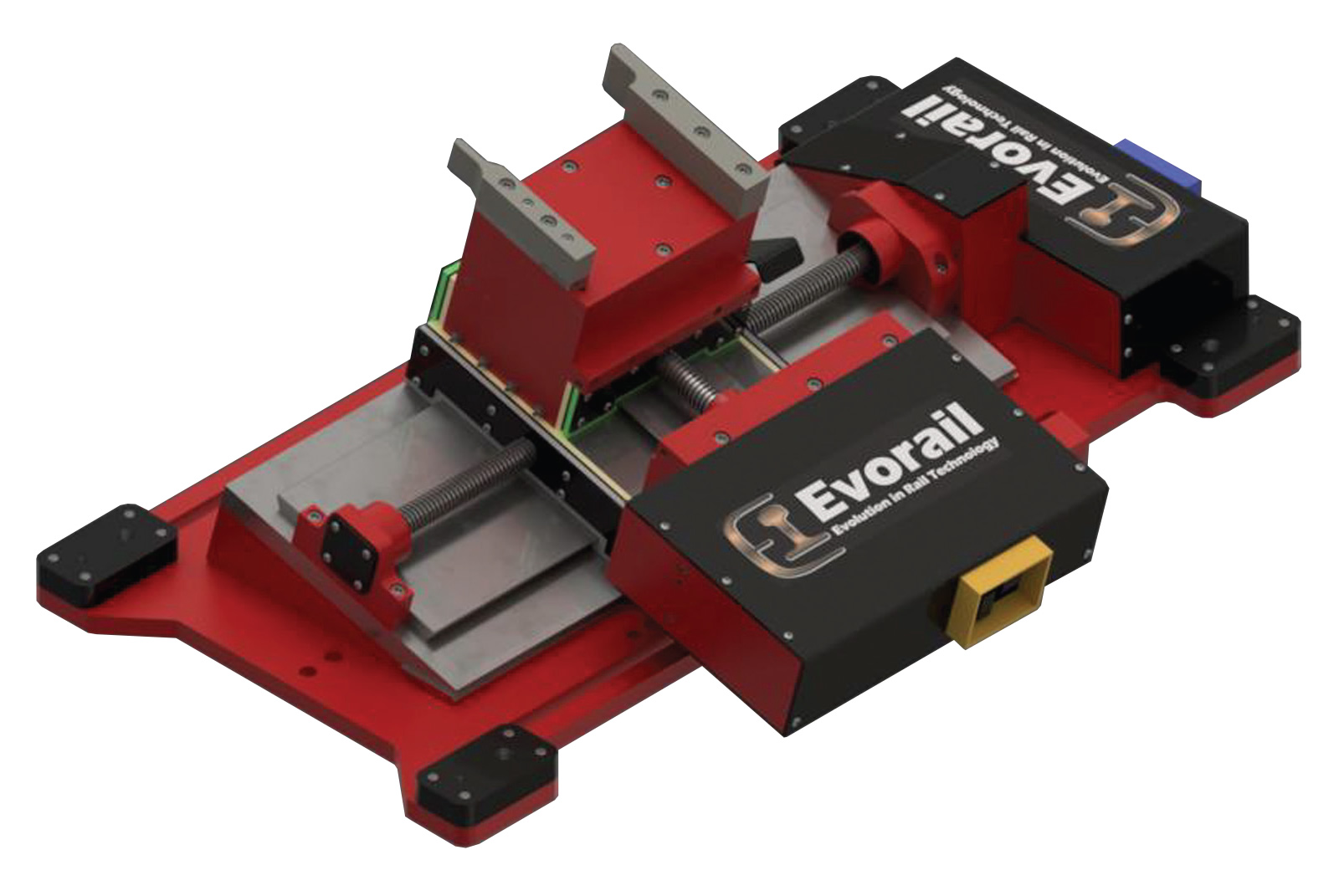

Shunting Locomotives Design and Manufacturing

Evorail has developed in-house capabilities to design and manufacture shunting locomotives for metre-gauge, Cape-gauge, and standard-gauge railways. This is supported by over a decade of our team’s experience across the continent in designing, manufacturing, and maintaining locomotives, Evorail produces 3-axle, diesel-powered shunting locomotives capable of developing up to 950 hp continuously.